YEARS OF EXPERIENCE

PLANTS BUILT THROUGHOUT THE WORLD

SAMPLERS

SINCE 1982 DV S.R.L. HAS BEEN PROJECTING, MANUFACTURING AND REALIZING

SOLUTIONS FOR THE AGRO-FOOD INDUSTRY

News

WATER PURIFICATION

AND TREATMENT SYSTEM

FOR VEHICLE WASHING AREA

Plant with oil separator, biological processing and refinement with wastewater filtration for washing area for farming vehicles and tractors.

Sampling solutions

STORK PRO

The new generation

of sampling systems

STORK PRO is part of the new generation of grain and cereals samplers distributed in more than 25 countries worldwide.

Visit our dedicated website for more information

Projects

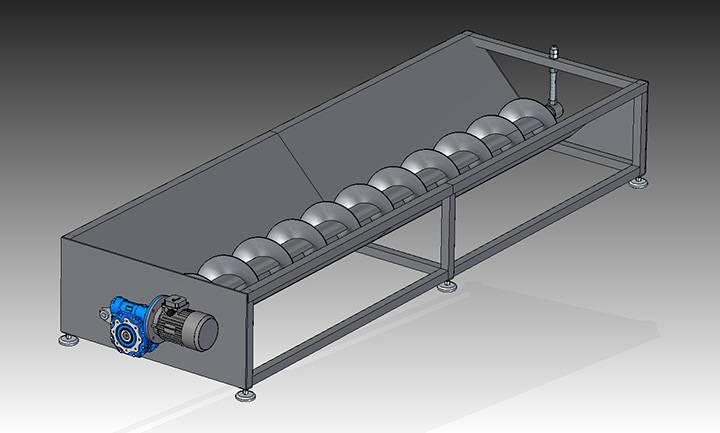

CUSTOMIZED SOLUTIONS

FOR WINE PRODUCTION

We design and realize customized solutions and systems for wine-making facilities using 3D Solid Edge. Each plant is designed and built to meet specific needs of our customers, leveraging our 37 years of expertise in designing and manufacturing grape collecting tanks, belt conveyors and elevators, screw conveyors and elevators.

SOME OF OUR FACILITIES

Carpenè Malvolti

Treatment plant with membrane filtration.

Since the treatment plant was built within a residential neighborhood, the project aim was the reduction of plant machinery visibility and acoustic impact.

Pieve di Soligo (TV) Italy

Wine Cellar

Cantina Codroipo

Supply of grape collecting tanks and screw conveyors for grape-skins and stalks evacuation.

Codroipo (UD) Italy

Wine Cellar

Grain Corp Australia

STORK COMPACT sampling system for trucks and rail wagons installed in the largest collection center in the southern hemisphere.

Moree (Australia)

Grain storage center

A few of our references

Treatment plant with membrane filtration.

The project involved the renovation of vertical stainless steel tanks and the adoption of a multi-jet aeration system.

The plant is equipped with a remote control system for monitoring of all management parameters via modem.

Tenuta Belcorvo

Godega di Sant’Urbano (TV), Italy

Treatment plant expansion project.

The treatment plant was expanded with the introduction of a storage tank with an innovative aeration and mixing system that has allowed the doubling of the treated flow rates.

The tank is completely underground to allow the movement of agricultural vehicles during the grapes harvest.

Cantina Rauscedo

Rauscedo (PN), Italy

Treatment plant with membrane filtration.

The Wine Cellar is characterized by an unusual variability of flows in different seasons so the plant has been realized with three distinct oxidation stages that can be excluded during periods of low load.

The plant is equipped with an innovative remote control system that allows the integrated management and monitoring by video camera.

Colli del Soligo

Pieve di Soligo (TV), Italy

Stork Rail 10 meters Sampling System wall-mounted. Plant in Parma, Italy.

Barilla Group

Parma, Italy

Stork Rail and Compact Sampling Systems with new hybrid technology. Plants in Apulia and Tuscany, Italy.

Casillo Group

Corato (Ba), Italy

Stork Rail Sampling System equipped with semi-automatic sampling system complete with inverter and touch Screen PLC. Plant in Padua, Italy.

Molino Rossetto

Padova, Italy

Grape collecting tanks and belt and screw conveyors and elevators. Various facilities.

Gruppo Collis

Monteforte d’Alpone (VR), Italy

Grape collecting tanks and belt and screw conveyors and elevators. Various facilities.

Cantine Moncaro

Montecarotto (AN), Italy

Grape collecting tanks and belt and screw conveyors and elevators. Plant in Montalcino.

Castello Banfi

Montalcino (SI), Italy

CONTACT US